Our Vision

We are the Top-runner of analytical laboratories.

Our certificates are the best choice for practical global use.

Our quality is based on the deep knowledge, diverse experience and good technology.

Our quality consists of consistent quality control system from sample reception to the issue of certificates.

In addition, we practice training programs and PDCA cycle for daily analytical activities.

The High Quality test data

JFRL is an ISO 9001 certified laboratory and have established and is operating a quality management system.

We also obtained ISO/IEC 17025 and JNLA laboratory certifications to part of the test items.

In addition, we have been evaluated for GMP compliance in the pharmaceuticals field and GLP compliance in the medical devices and pesticides field.

Regarding other analytical requests, we have established a system that can provide reliable results by fundamentally satisfying the following requirements for ISO/IEC 17025:

1. Widely accepted and validated test methods

2. Calibrated equipment, and reference materials traceable to national standards

3. Technically competent analyst

4. Ensuring traceability of samples and results

5. Developed testing environment

6. Implementation of Internal Quality Control

7. Active participation of domestic and international proficiency test

cf ・FSSC 22000 guidance on Appendix ⅠA, The following provides additional

information relating to questions arising from the revised requirements

・APLAC Guidelines for Food Testing Laboratories

To provide the reliability data

STEP

01

Client

STEP

02

Reception

Reception

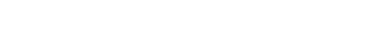

As soon as we receive a sample, we register it in our computer system.Each sample is recognized with eight digit unique number and barcode on the sample label.

Photos of the sample records the current conditions.

The electronic data of the order information is sent to our laboratories.

STEP

03

Traceability

Traceability

Laboratories section personnel also check the order information and samples.

STEP

04

Method Control

Method Control

We select the analytical method according to the purpose of clients. Each method is validated and verified by ourselves.

STEP

05

Sample Control

Sample control

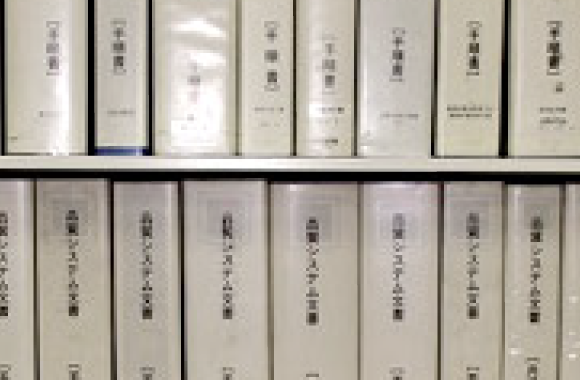

Storage condition is indicated on the sample label.

We keep the sample in a

temperature-controlled refrigerator or freezer to meet requirement of the assays.

Sample preparation for analysisAccording to the matrix, a sample is prepared by the appropriate method.

We develop techniques to prepare various types of samples.

STEP

06

Reference Standard Control

Reference Standard Control

Every reference standard has the management number for traceability.

STEP

07

Apparafus Control

Apparatus Control

In order to meet requirements of clients, we have a variety of analytical instruments.

Every apparatus has the management number.

We achieved the total equipments control plan (DQ, IQ, OQ, PQ).

STEP

08

Internal Quality Control

Internal Quality control

Our personnel are well trained and qualified for all analytical service. To avoid crossing samples, we use the barcode on the sample label. Internal quality control system using reference materials and recovery tests confirms quality of our tests.

STEP

09

Test Report

Test Report

The test data certified by the section head of laboratory are transmitted electronically to the section of analysis documentation. We issue the report and send it to the client.

STEP

10

Client

The PDCA cycle of a Quality system

Plan

Quality policy(Our goal)

Training program

Do

Laboratory management

(Sample control / Apparatus

control / Reagent control /

Traceability)

Control of documents

and records

Human resources

Training

We have the annual training program. The textbook and the trainer is designated by the Training Committee. Also each section has the OJT training program. Our laboratory manager confirms the skills and knowledge of personnel by skill evaluation test.

Check

Internal audit

Internal audit

Based on ISO9001 quality management system, the head of Department of Quality Assurance submits an annual audit plan. The trained members audit all sections and confirm the conditions of quality management system.

If nonconformity is found in the audit, a corrective action is done as soon as possible.

PDCA cycle develops our Quality control system.

Internal quality control

Proficiency testing Information

From client

From client

ACT

Corrective and preventive action

Quality System Committee

Management review

- P

-

Plan

Quality policy(Our goal)

Training program

- D

-

Do

Laboratory management(Sample control / Apparatus control /

Reagent control /Traceability)Control of documents and records

Human resources

Training

We have the annual training program. The textbook and the trainer is designated by the Training Committee. Also each section has the OJT training program. Our laboratory manager confirms the skills and knowledge of personnel by skill evaluation test.

- C

-

Check

Internal audit

Internal audit

Based on ISO9001 quality management system, the head of Department of Quality Assurance submits an annual audit plan. The trained members audit all sections and confirm the conditions of quality management system.

If nonconformity is found in the audit, a corrective action is done as soon as possible.

PDCA cycle develops our Quality control system.

Internal quality control

Proficiency testing InformationFrom client

From client

- A

-

Act

Corrective and preventive

action Quality System

CommitteeManagement review